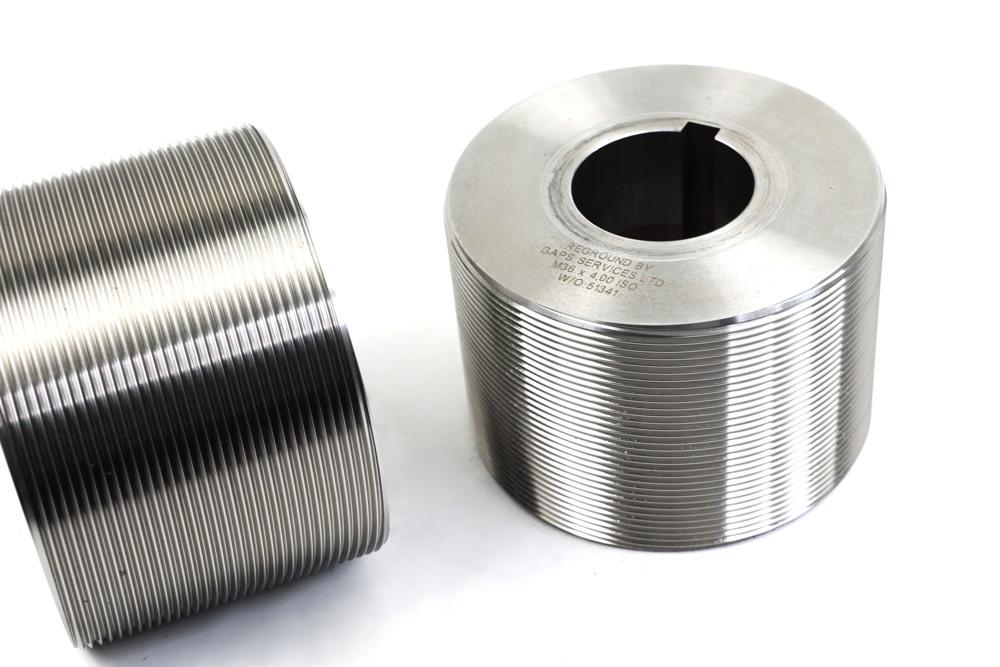

We manufacture a range of styles of cylindrical dies to suit different applications.

Plunge dies, annular through feed dies, helical through feed dies and radial dies can all be produced at different face widths, diameters and bore sizes and both two and three-roll machines can be accommodated.

All popular machines are catered for including Steinle, Pee Wee, ORT, Reed, and Seny as well as lesser-known machines.

We can supply inspection reports to demonstrate conformity across any circular dies produced. As well as providing new tools, we also offer a regrind service on any die.

Manufactured to any grade

Our cylindrical dies can be manufactured in any grade of material for commercial or industrial use. For motorsport or aerospace applications, more highly alloyed materials can be used.

No job is too hard

We combine our high alloy materials with different heat treatments so GAPS’ dies are capable of rolling fasteners, which in age-hardened condition are traditionally difficult to produce. Rolling Inconel or Multi-Phase materials can be done with ease, especially when the dies are pitch-corrected for hot rolling applications.

Improved wear and resistance

Where appropriate, surface treatments can also be applied to improve wear resistance and die life. Radius Run-Out (RRO) features on all our plunge circular thread rolling dies.

Regrind service

We offer a full regrind service on all cylindrical dies. The regrinding of used tools offers significant cost-savings and environmental benefits when compared with purchasing new.