Our state-of-the-art production facility is equipped with a range of advanced machines and technologies including the Flexium Control System, both manual and CNC Matrix Grinding Machines, Flat Die Machines, Turning and Surface Grinding machines, and Laser Markers.

These cutting-edge machines enable us to produce high-quality tooling solutions with precision and accuracy, ensuring our customers receive the highest standards of products and services.

Our team of skilled engineers and technicians utilise these machines to manufacture and supply customised tooling solutions to meet the specific requirements of our customers across various industries.

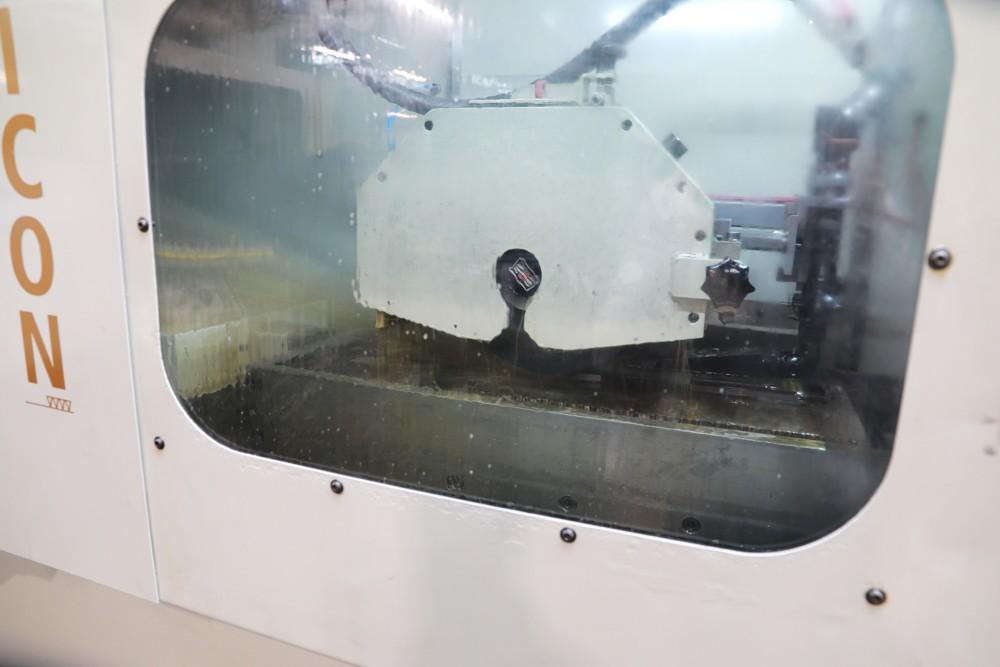

Flexium

Two custom machines, designed and built in house which are dedicated to grinding internal tooling crushers.

Manual Matrix Grinding Machines

Nine machines, generally used for the thread grinding of Circular dies, Axial Rolls, T-Rolls and Chasers.

CNC Matrix Grinding Machines

Four custom-built CNC machines with Matrix bases, used for grinding cylindrical dies, radial rolls and other specialist jobs such as ball screws.

Flat Die Machines

Three CNC flat die grinding machines with custom-built software. One Thompson, one Jones & Shipman and one Elb.

Soft Section

One factory area is dedicated to turning and milling the raw material to size for blank production. This is done through a variety of CNC lathes and milling machines.

Surface Grinding

Our surface grinding section comprises of a selection of vertical spindle segmental grinders, ring grinders and reciprocating surface grinders.