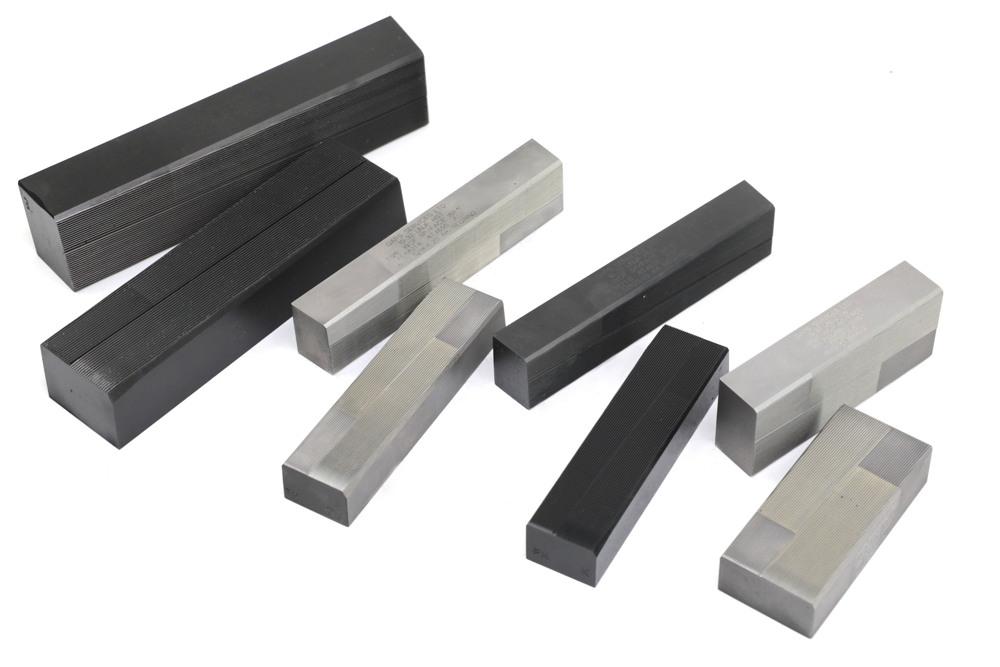

We manufacture flat thread rolling dies to suit all common machines, including Waterbury Farrel, GW Menn, Saspi, Ingramatic and Hilgeland.

We specialise in the production of controlled root dies (UNJ & MJ series) as used in the high-volume aerospace sector, but all machine screw profiles can be accommodated. Where required, we have the expertise to supply dies that are suitably pitch corrected for hot rolling applications, and as well as providing new tools, we also offer a regrind service on any die.

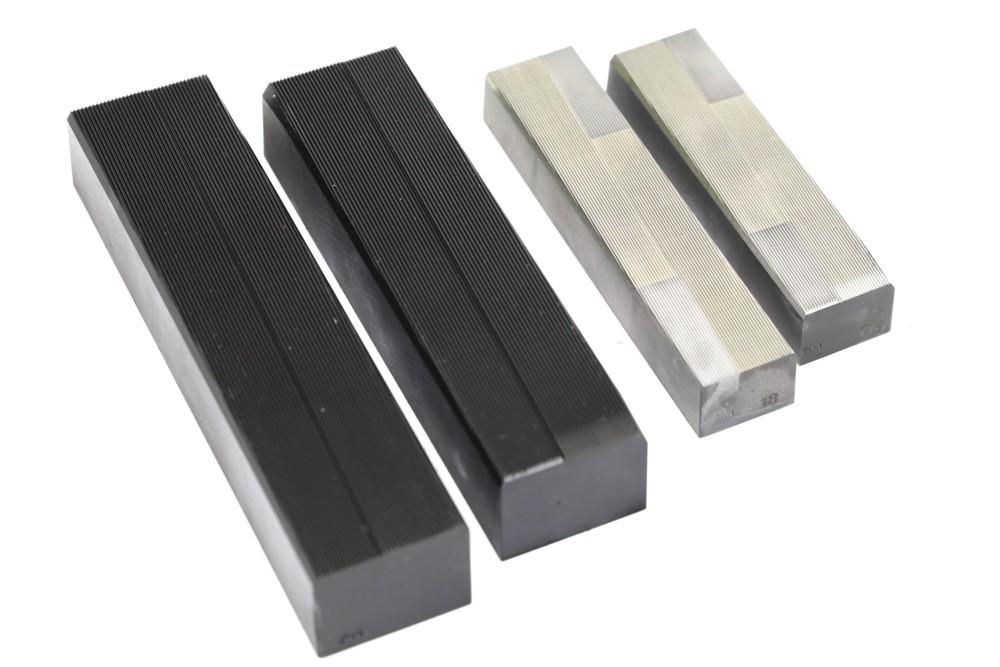

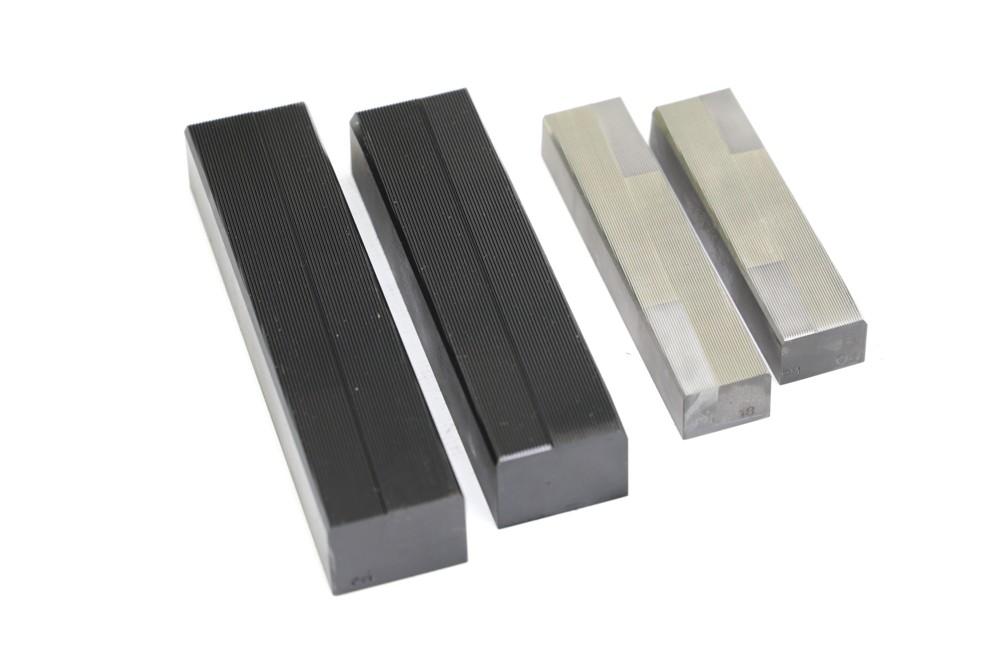

Single-face, split-face and duplex dies can all be produced.

Absolute accuracy

Our controlled manufacturing process, performed on bespoke 4-axis CNC thread grinders ensures absolute accuracy and consistency from die to die and batch to batch. The extremely tight tolerances applied to the entire manufacturing process combined with stringent inspection and quality controls guarantee die geometry and dimensional accuracy.

Improved die life and resistance

The use of advanced materials and surface treatments improves die life and wear resistance, providing high output. All dies feature Radius Run-Out (RRO) which improves the tensile strength of the fastener by reducing the stress points. Dies with RRO are less likely to chip because all sharp areas are removed and smoothed in a controlled manner. A full inspection report can be provided with any batch of tools.

Quick set up

Dies are produced as matched pairs, facilitating quicker set-ups with minimal downtime. With longer batch runs possible, our flat dies reduce time lost to changeovers and save on laboratory inspection time.

Regrind service

We offer a full regrind service on all flat dies. The regrinding of used tools offers significant cost-savings and environmental benefits when compared with purchasing new.