A UK tooling manufacturer with true global reach, we specialise in precision thread ground tooling for the production of rolled fasteners.

We are experts in the design and manufacture of high-quality thread rolling dies. Our tools roll millions of precision fasteners each week that are used in aerospace, motorsport, automotive and beyond.

Quality is at the heart of the GAPS business and we maintain an ISO 9001-2015 certification to guarantee that our products meet the highest of standards.

Trusted by

40+ years of tool grinding experience

At GAPS, we have delivered exceptional accuracy and quality to our client base for over 40 years. With a vast depth of technical knowledge, experienced engineers, bespoke CNC thread grinders and a suite of inspection equipment, we are the business you can trust when it matters.

We can grind customer-supplied blanks or provide full tooling solutions, tailoring the material, heat treatment and coating to suit the needs of the client.

40+ years of tool grinding experience

At GAPS, we have delivered exceptional accuracy and quality to our client base for over 40 years. With a vast depth of technical knowledge, experienced engineers, bespoke CNC thread grinders and a suite of inspection equipment, we are the business you can trust when it matters.

We can grind customer-supplied blanks or provide full tooling solutions, tailoring the material, heat treatment and coating to suit the needs of the client.

Quality above all else

Our key focus is always on quality and we pride ourselves on the accuracy and consistency of our tooling which results in reliable and repeatable fastener production.

We can provide almost any thread form and pitch across our product range and offer a regrind service for both flat and circular dies.

We’re committed to excellence

Great quality tooling and customer satisfaction is at the heart of our business. Everyone, from our highly trained engineers and office management team to our apprentices, work to deliver the best possible customer experience.

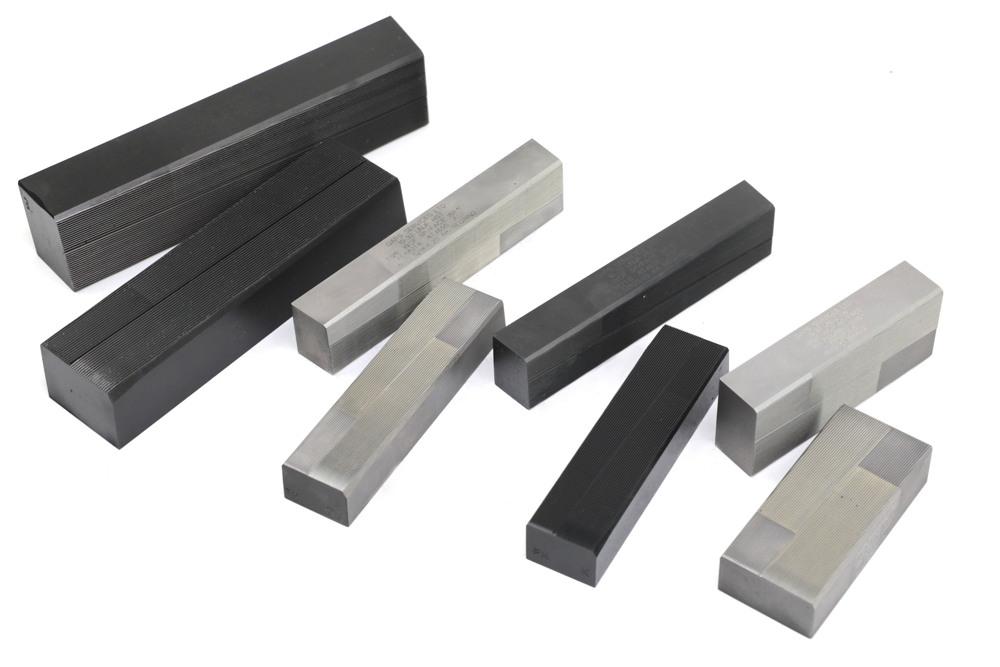

A comprehensive product range

With unique specialised manufacturing techniques honed over decades, we offer a comprehensive product range including flat dies, cylindrical dies, axial rolls, tangential rolls and radial rolls. These products cover all standard UNJ, UN, MJ, ISO, BSP, Whitworth, Trapezoidal and Acme forms. We can also produce tools with forms conforming to customer drawings where required, and offer a comprehensive regrind service.

For applications demanding rapid turnaround, use our readily available stock. We maintain a wide blank inventory in a variety of sizes and hardness specifications that are ready to grind.

Regrind specialists

To help you with return on investment from your tool purchases, we can regrind your used flat or circular dies. We will regrind dies manufactured by GAPS or by third parties and are able to convert from one pitch / form to another when required.

If your dies have been damaged whilst in production, this is no problem, we have the ability to reduce diameters or face widths accordingly.

Explore our products

Flat Dies

We manufacture flat thread rolling dies to suit all common machines, including Waterbury Farrel, GW Menn, Saspi, Ingramatic, and Hilgeland.

learn more

Cylindrical Dies

Plunge dies, annular through feed dies, helical through feed dies and radial dies can all be produced at different face widths, diameters and bore sizes. Both two and three-roll machines can be accommodated.

learn more

Regrinds

We offer a full regrind service on all flat and cylindrical dies. The regrinding of used tools offers significant cost-savings and environmental benefits when compared with purchasing new.

learn more

Axial Rolls

Our commitment to quality and excellence means customers trust our rolls to deliver consistent, accurate results, time and time again. Our huge range of in-stock blanks are ready to go.

learn more

Radial / Incremental Rolls

Eccentrically ground precision thread rolls designed for progressive, single-revolution fastener production.

learn more

Tangential Rolls

High speed thread rolls for the production of short thread lengths where it is required to roll into the undercut or behind the shoulder of a fastener.

learn more

Ready to deliver